Our CIPP Process

Our CIPP Process

Our signature trenchless repair process is timely, innovative and customized. If you’re thinking about using CIPP pipe repair for your building, here’s what you can expect.

Video Camera Inspection

All trenchless pipe repair should start with a video camera inspection. We will run a video camera through your pipes to get a clear picture of the damage. This way, you and our team can see the extent of the damage, and we can recommend a course of action.

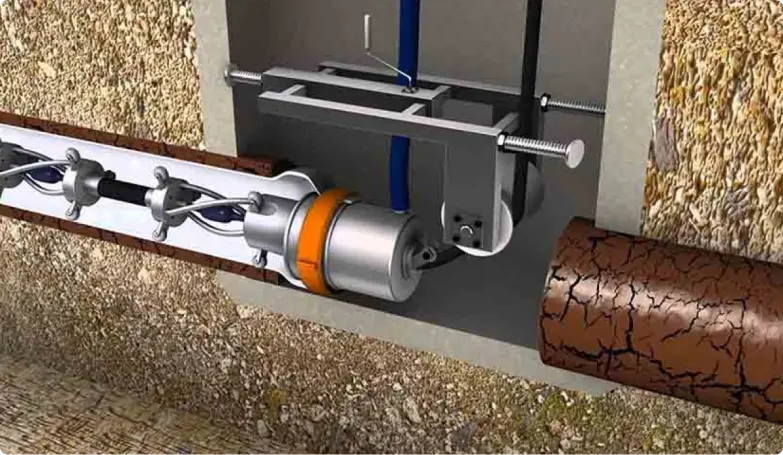

Trenchless Repair Insertion

The next step is inserting the CIPP liner into the pipe. We will insert the liner into the broken pipe from a 3’x3’ access pit or similar access point, so there’s no need to dig a big hole on your property. Once it’s fully inserted, the CIPP liner will run along the inside of the broken pipe.

Drying Time

Next, you’ll wait for the CIPP liner to cure (harden). Normally, this part only takes 45 minutes. You can even speed up the process with hot water or steam. During this process, the CIPP liner adheres itself to the host pipe, sealing away cracks and holes. Once your liner has dried, you can use your pipes just as you normally would.

Final Inspection

We will take one last look at the repaired pipe and a second video camera inspection will show the results of the CIPP repair. Once again, you will be able to see the results for yourself.